2022-04-11

Briefly describe the maintenance skills of fiber laser cutting machine voltage stabilizer

2022-04-11

Laser drilling size and precision control of metal laser cutting machine

2022-04-11

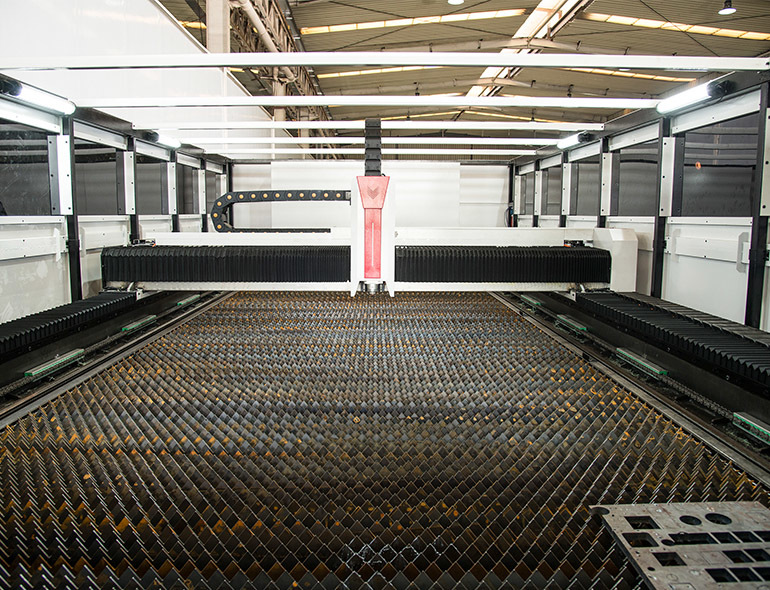

Changchang Laser teaches you how to choose a metal laser cutting machine

2022-04-11

How can the metal laser cutting machine make the plate cutting smoother?

2022-04-11

Laser drilling size and precision control of metal laser cutting machine

2022-04-11

Briefly describe the maintenance skills of fiber laser cutting machine voltage stabilizer

2022-04-11

How can the metal laser cutting machine make the plate cutting smoother?

2022-04-11

Brief introduction to the new trend of metal laser cutting machine

2022-04-11

Laser drilling size and precision control of metal laser cutting machine

"Long winds and waves, long history!" Changchang Laser marched forward bravely, deeply cultivated in the field of metal forming machine tools, helped the transformation and upgrading of the manufacturing industry, and jointly created a great cause of rejuvenation!

Follow official WeChat

2022 Dongguan Changchang Laser Intelligent Equipment Co., Ltd. All rights reserved 粤ICP备18038369号